Using an epoxy resin is a delicate business that requires precision. Despite the utmost care, it is virtually impossible to prevent any mistake for an epoxy craft.

You are bound to come across at least one of these problems listed below. But don’t you worry! We’ve made sure to offer apt solutions for each one of these to bring you seamless craftsmanship of epoxy resin. Let’s troubleshoot:

The Annoying Particles

You will come across this problem the most. Something like an insect, fly, or debris may fall in your wet epoxy. That can ruin the appeal of your epoxy resin. To prevent anything like that, you can utilize a wooden stick or a tweezer to pick the foreign object and discard it.

***The best way to eliminate this problem is to prevent it. Use a clean box or container to cover the project.

However, make sure that you do it while the epoxy is still wet. Once it starts gelling or hardening, this becomes problematic.

Melancholy Of Uneven Surface

You can solve these problems by utilizing a perfectly flat surface underneith your project. Take control of the temperature of your room and make sure that epoxy dries out and hardens evenly. Ensure proper ventilation and low humidity is maintained. Eliminate bubbles with the use of a torch or heating device to release bubbles.

Waves And Ripples

Another widespread problem you may encounter is the formation of waves and ripples in the epoxy resin. It is seemingly unavoidable when working with wood. The single best solution for this is to use an extra coating of epoxy resin to pre-treat the wood. Additionally, a seal coat provides an extra layer to the epoxy, which will prevent bubbles as well.

For the final touch, add a final flood coat for a seamless finish.

Get Epoxy Resin Supplies

One thing you have to make sure of is to use fresh and premium-grade supplies for an elegant epoxy resin design. For that, you can visit our website. If you’re looking for other similar guides and articles, then you can find us on social media. We strive to bring the best piece of information for you: https://www.theepoxyresinstore.com/

Hope this was helpful.

Let us know what you would like to create below in the comments.

**If you made it this far down, We occasionally pick the best comment to win a giveaway. -hint-hint

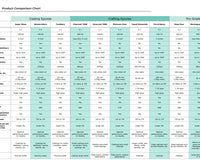

We created a handy comparison guide to help understand the different properties of our epoxy resin. Just follow this link here https://www.theepoxyresinstore.com/blogs/news/what-epoxy-resin-is-best-for-my-project

https://www.theepoxyresinstore.com/ is an expert manufacturer of various epoxy resins that can be used for both craft projects and industrial applications.

We also offer colors, pigments, glitter, and other additives for various epoxy resin projects.

- All in one store - The Epoxy Resin Store

support@theepoxyresinstore.com

Phone: (951) 677-0400

Address: 540 Crane St suite A Lake Elsinore, CA 92530

https://www.theepoxyresinstore.com

Social Accounts:

https://www.facebook.com/TheEpoxyResinStore

https://twitter.com/epoxyresinstore

https://www.linkedin.com/company/the-epoxy-resin-store

https://www.youtube.com/channel/UC3NKcCrYL5uHK-sH5XMQ9HA

https://instagram.com/theepoxyresinstore

#epoxyresin #resinart #epoxy #resin

11 comments

Marie Lanier

I get sticky spots on the surface when I pour in my cutting board silicone molds. Why would that happen?

Randall Eby

Do you have small quantities like pints?

Want to learn and practice before I go whole hog.

Jackie Brunty

I have been wanting to pull up carpet in bedroom ,and do a epoxy floor will that work what do you suggest ???

Jackie Brunty

I have been wanting to pull up carpet in bedroom ,and do a epoxy floor will that work what do you suggest ???

Gabby Castro

I love this product, I use the 7050 for my projects. I don’t have to use a mask when mixing the resin, and it is truly clear. While mixing I get bubbles but they’re easy to get rid of which is a 👍🏽👍🏽. I also always receive emails for discounts! Recommend it to anyone with or without experience 😊 five stars for me ⭐️⭐️⭐️⭐️.

Wayne nicely

I have a in ground swimming pool that has a about 8” split in the step going into the pool it’s a fiberglass step I need something that I can put on under the water

Drew Petersen

We did not receive any instructions on mix ratios. What is the mix ratio?

Kenny james

I have used yhe epoxy store resin and it is a fantastic product

The customer service is 2nd to none

john

thanks! great tips

John McCormick

I’m building some small dinning tables out of reclaim red oak flooring. Which I ran through a planner to remove original finish. Im having a problem with very small tiny bubbles everywhere. As soon as I pop them with heat they come wright back even more within seconds. Never had this problem with Pine, red cedar, magnolia, hickory, sweet gum, oak or spruce.

Thanks JMc

Michael Bartone

Thanks for that information it was helpful .I already use your website to get advice , you have a new customer.